What is scale?

Scale is an agglomeration or mass of inorganic and/or organic diamagnetic crystals bonded together. The well known examples are calcium carbonate and paraffin.

Why does scale form?

Scale crystals carry electrical charges – positive and negative. These electrical charges concentrate on the sharp edges of the scale crystals. The sharper the edges, the stronger the charge. The stronger charge results in larger crystals and stronger crystal bonding.

The bonding of one scale crystal to another scale crystal and/or to the walls of a pipe or vessel is a function of the attraction between positive and negative charges on the crystals and/or the vessel walls.

Scale is an Electrical Problem

Logic calls for an electrical solution to an electrical problem. Scale deposition is also not a chemical problem. It is an electrical problem resulting from the attraction between positive and negative charges. An electrical solution is the only way to approach, reduce and prevent crystal bonding (scale deposition).

Effect of a Magnetic Field on a Diamagnetic Substance in Motion

Diamagnetic substances react differently under the influence of magnetic fields to how paramagnetic and ferromagnetic substances react.

When a diamagnetic substance is passed through a magnetic field under certain conditions, the angular velocity of the electrons is increased, and subsequent to passing through the magnetic field the electrons continue to revolve at their new higher velocity, that is, the electrons remain in the higher energy or excited state. “Electricity and Magnetism”, – Second Edition, – by Ralph P Winch, Prentice-Hall Inc, NJ

These higher energy crystals results in changes in the characteristics of the treated scale crystals. It is to be noted that water is also diamagnetic and its characteristics are altered by passing through a magnetic field.

The additional energy of the treated crystals (and of water in an aqueous solution) can share/transfer that energy to existing scale crystals. This results in the weakening of the crystal bonding of the existing crystals which are then washed away (removed) by the flowing fluid.

Scale X Technology Magnetic Fluid Conditioners are based on well known scientific principles

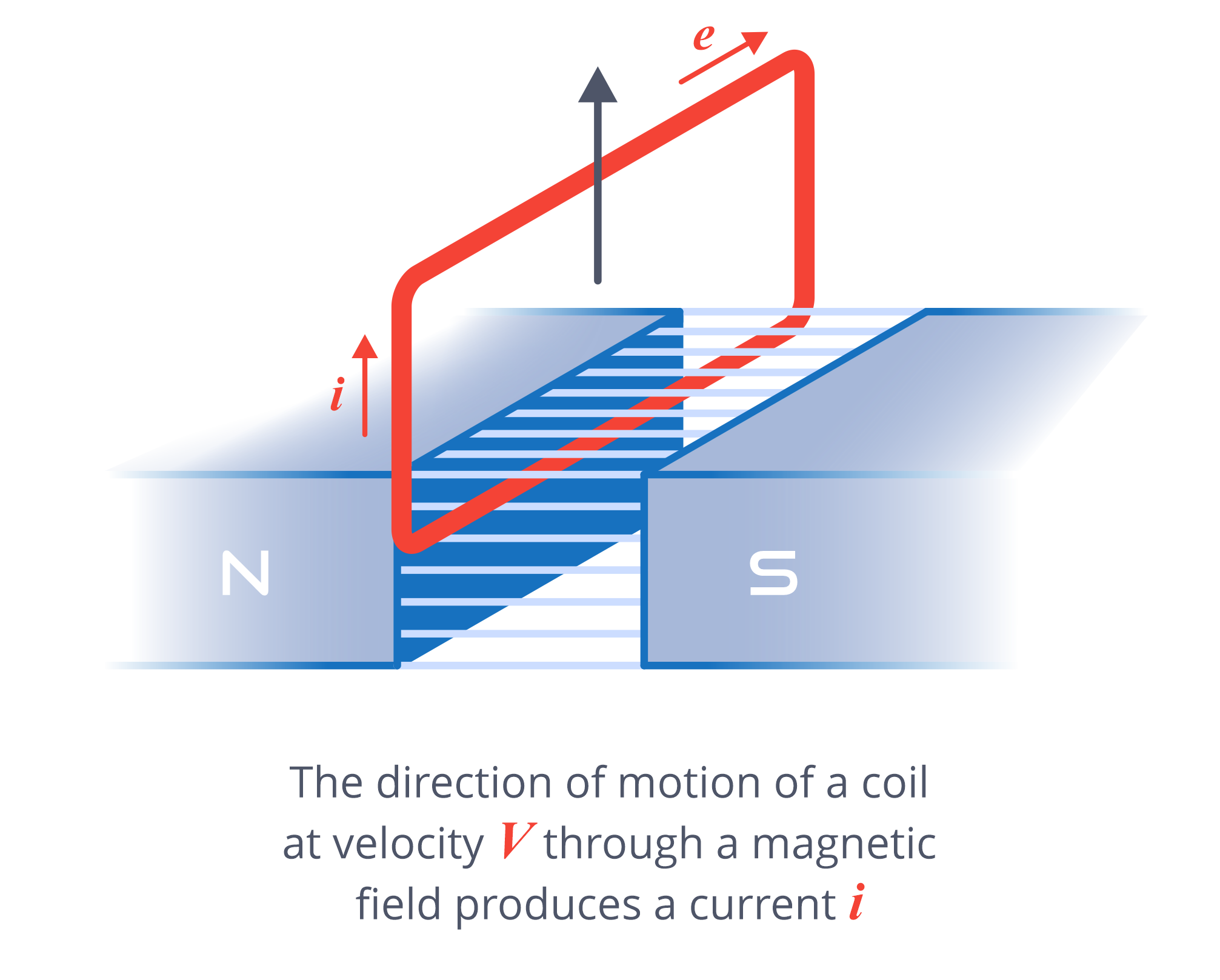

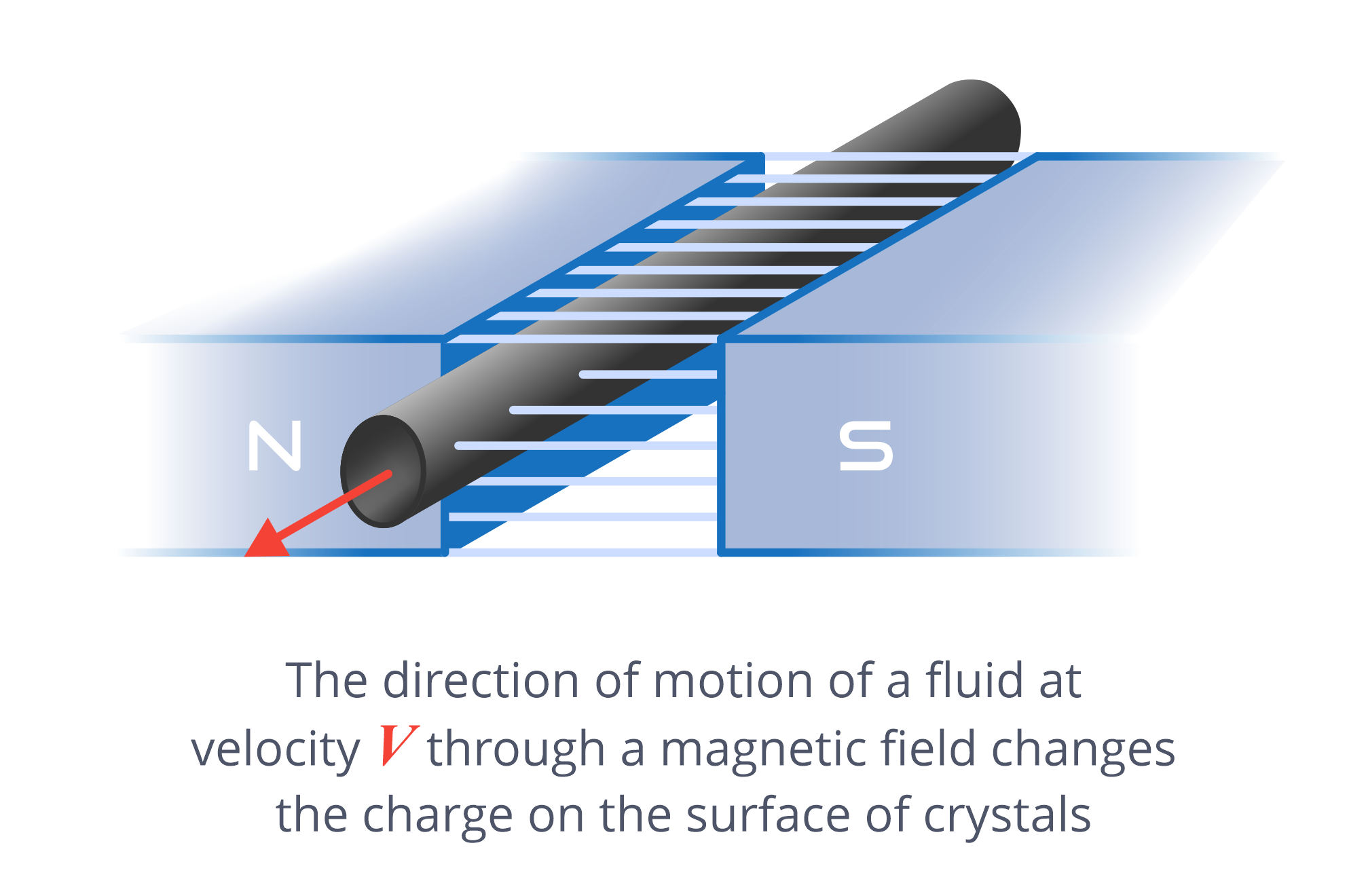

The Scale X Technology is based on the principles which relate to the interaction between a magnetic field and the charge on the diamagnetic scale crystals as the fluid passes through the magnetic fields. The same principals are used in electric generators, that is, the interaction between a magnetic field and a metallic conductor (coil) passing through the field which causes an electric current (electric charge) to flow through the conductor.

Effects of motion of a coil wire and a fluid through a magnetic field

Not so well known is the effect of a magnetic field on a fluid flowing through the magnetic field. The American Petroleum Institute in a paper released at the 45th Annual Meeting of the International Water Conference in 1984 stated:

“A fundamental law of physics states that the motion of a conductor through a magnetic field will cause a voltage to be produced. This principle of electromagnetic induction was first demonstrated by Faraday, and applies not only to conducting solids such as wires, but also to conducting fluids such as aqueous solutions containing dissolved electrolytes.”

What we know empirically

The observable changes to diamagnetic substances when magnetically treated:

The effect of the magnetic field (correctly applied) on water results in:

Benefits of Scale X Technology Magnetic Fluid Conditioners

Magentic Fluid Conditioning VS Chemical Inhibitors

Block Valve Reducer

Reducer located after let down valve.

Water Line Control Valve

Valve let down pressure was 1300kPa.

(move divider on images left and right)